167x Filetype PPT File size 2.46 MB Source: tid.uio.no

Contents

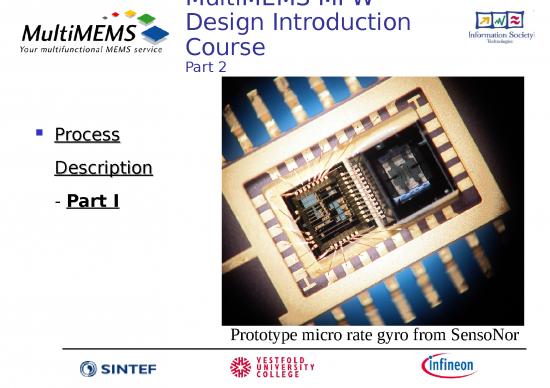

Process Description, Part I

Cross section overview

Key process features

MPW process step-by-step

Process Description, Part II

Process Description, Part II

Absolute limitations

Absolute limitations

Process monitors

Process monitors

Test data

Test data

Slide 2

Cross section

overview

Slide 3

Silicon

Micromachining

Micromechanics in silicon is here defined as three-

dimensional micromachining in single crystal

silicon by means of photolithographic etching

techniques.

This definition covers most techniques used to make

micromechanical sensors, although in some cases

additive structures such as polysilicon and silicon

dioxide also have been micromachined by selective

etching techniques, and in some cases mechanical

drilling or other machining methods are used.

Crystal Structure of Single Crystal Silicon

Isotropic and anisotropic etching

etc

Slide 4

Silicon

Micromachining

Micromechanics in silicon is here defined as three-

dimensional micromachining in single crystal

silicon by means of photolithographic etching

techniques.

This definition covers most techniques used to make

micromechanical sensors, although in some cases

additive structures such as polysilicon and silicon

dioxide also have been micromachined by selective

etching techniques, and in some cases mechanical

drilling or other machining methods are used.

Crystal Structure of Single Crystal Silicon

Isotropic and anisotropic etching

etc

Slide 5

Crystal Structure of

Single Crystal Silicon

It is a face-centred

cubic structure

(diamond structure)

with two atoms

associated with

each lattice point of

the unit cube.

One atom is located

in position with xyz

coordinates (0, 0,

0), the other in

position (a/4, a/4,

a/4), a being the

basic unit cell

length.

It is best to use a

“hardware” model

to see it in 3

dimensions

Slide 6

no reviews yet

Please Login to review.