154x Filetype PDF File size 0.40 MB Source: intrans.iastate.edu

Timber Preservation

Treatments for Highway

Applications

tech transfer summary

October 2007 Wood preservatives are evaluated for their performance effectiveness

in building new timber bridges in Iowa.

RESEARCH PROJECT TITLE Objective

Field Evaluation of Timber Preservation

Treatments for Highway Applications The primary objective of this research was to evaluate the performance of

different wood preservatives in the fi eld and to review current specifi ca-

SPONSORS tions and testing procedures to determine whether they provide the level

Iowa Highway Research Board (TR-552) of timber treatment required for acceptable performance.

Iowa Department of Transportation

(CTRE Project 06-252) Problem Statement

PRINCIPAL INVESTIGATOR Timber can be a cost-effective building material for new bridge construc-

Terry J. Wipf tion. The single most limiting factor for increased use of timber bridges

Professor, Civil, Construction, continues to be concerns with durability. The durability of timber

and Environmental Engineering bridges is largely a product of the initial preservative treatment used to

Iowa State University

515-294-6979 protect the wood, although construction practices and maintenance also

tjwipf@iastate.edu play an important role.

CO-PRINCIPAL INVESTIGATOR Proper preservative treatment creates an excellent barrier against fungi

F. Wayne Klaiber and insects, which can destroy the wood; however, the preservative

Professor, Civil, Construction, barrier can be compromised during on-site installation or as a result of

and Environmental Engineering checks and cracks from normal weathering and moisture changes. Any

Iowa State University

515-294-7622 break in the treatment barrier may expose untreated wood to fungal or

klaiber@iastate.edu insect attack.

AUTHORS The Iowa State University Bridge Engineering Center (BEC), in conjunc-

Jake J. Bigelow, Carol A. Clausen, tion with the United States Department of Agriculture Forest Products

Stan T. Lebow, and Lowell Greimann Laboratory (FPL), evaluated the various types of wood preservatives

BEC used in Iowa and outlined recommendations for their use in new bridge

Iowa State University construction.

2711 S. Loop Drive, Suite 4700

Ames, IA 50010-8664 60

515-294-8103

www.bec.iastate.edu

50

The Bridge Engineering Center (BEC) is part 43 Yes No

of the Center for Transportation Research 42

and Education (CTRE) at Iowa State Univer- 40 38

sity. The mission of the BEC is to conduct 33

research on bridge technologies to help 30

bridge designers/owners design, build, and 25

maintain long-lasting bridges. Number of Counties

21

The sponsors of this research are not respon- 20 17

sible for the accuracy of the information 14

presented herein. The conclusions expressed

in this publication are not necessarily those 10

of the sponsors.

0

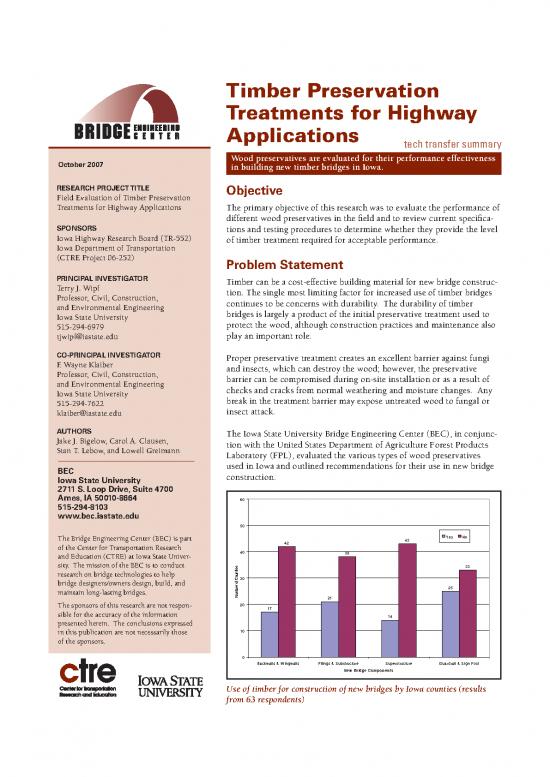

Backwalls & Wingwalls Pilings & Substructure Superstructure Guardrail & Sign Post

New Bridge Components

Use of timber for construction of new bridges by Iowa counties (results

from 63 respondents)

Research Description

The research team conducted on-site visual inspections of 47 Longitudinal

bridges in eight Iowa counties using different preservative splitting and

types. The goal of the inspections was to evaluate the perfor- cracking

mance of current preservatives used in Iowa. The following

preservative types were evaluated:

• creosote Vegetation growth—

• pentachlorophenol indication of decay

• copper naphthenate

• ammoniacal copper zinc arsenate (ACZA)

• chromated copper arsenate (CCA)

• alkaline copper quaternary (ACQ) Decay infi ltration

at cracks

When conducting the inspections, all available piles, cap

beams, backwalls, stringers, decking, and guard railing were

inspected for decay, physical defects, and damage—signs that

the preservative treatment is not performing effectively or may

have been compromised for future protection.

Preservative Evaluation

Highway applications of timber material in Iowa vary greatly Common visual signs of interior decay on bridge piles located

and include bridge pilings, abutment backwalls, guardrail in stream channels

posts, bridge deck planking and many others. Currently, vari- Plant-Applied Preservative Treatments

ous in-plant preservative treatments are being used in Iowa to

extend the service life of structures. Creosote has been the in- Plant-applied wood preservatives can be broadly classifi ed

plant preservative of choice for many years; however, due to as either oilborne or waterborne, based on the chemical

environmental concerns and handling issues, a movement is composition of the preservative and the solvent/carrier used

being made away from creosote to other preservative alterna- during the treating process. Generally, oilborne preservatives

tives. Remedial, or in-place, preservative treatments have seen are used with petroleum based solvents ranging from heavy

minimal usage in the state of Iowa. As Iowa’s timber bridges oils to liquefi ed gases. Waterborne preservatives are applied

become older, the implementation of in-place treatments will using water-based solutions, such as water and ammonia.

be necessary to reduce future costly repair and replacement. There are advantages and disadvantages associated with us-

ing each type that depend upon the application.

Estimated service life of treated round fence post in southern

Treatment Mississippi

barrier 90% confi dence

Average Estimated limits for service

Preservative retention service life (yrs)

3

Seasoning (lb/ft ) life (yrs) Lower Upper

cracks Copper

naphthenate 0.03 65 55 78

Penetration at Creosote 5.6 54 47 62

incising marks Pentachloro-

phenol 0.32 74 60 91

ACA 0.34 60 51 69

Pentachlorophenol treated railing post with fi eld-cut end grain Untreated 0 2.4 2.1 2.7

and no in-place treatment which increased the amount of

physical defects

Properties and uses of plant-applied preservatives for timber bridges

Standardized Preservative Solvent Surface Color Odor Fastener

Uses Characteristics Characteristics Corrosion

All uses Creosote Oil-type Oily, not for frequent Dark brown Strong, No worse than

human contact lasting untreated wood

All uses Ammoniacal copper Water Dry, but contains Brown, possible Mild, short Worse than

zinc arsenate arsenic blue areas term untreated wood

All uses Chromated copper Water Dry, but use is Greenish brown, None Similar to

arsenate restricted by EPA weathers to gray untreated wood

All uses (except Pentachlorophenol No. 2 fuel oil Oily, not for frequent Dark brown Strong, No worse than

in seawater) Type A (heavy oil) human contact lasting untreated wood

All uses (except Copper No. 2 fuel oil Oily, not for frequent Green, weathers Strong, No worse than

in seawater) naphthenate human contact to brownish gray lasting untreated wood

All uses (except Alkaline copper Water Dry, okay for human Greenish brown, Mild, short Worse than

in seawater) quat contact weathers to gray term untreated wood

All uses (except Copper azole Water Dry, okay for human Greenish brown, Mild, short Worse than

in seawater) contact weathers to gray term untreated wood

Above ground, Pentachlrophenol Mineral spirits Dry, okay for human Light brown, Mild, short No worse than

fully exposed Type C (light oil) contact if coated weathers to gray term untreated wood

Above ground, Oxine copper Mineral spirits Dry, okay for human Greenish brown, Mild, short No worse than

fully exposed contact weathers to gray term untreated wood

Above ground, Copper HDO Water Dry, okay for human Greenish brown, Mild, short Worse than

fully exposed contact weathers to gray term untreated wood

The most common oilborne preservatives are creosote, In-Place Preservative Treatments

pentachlorophenol, and copper naphthenate. Conventional

oilborne preservatives, such as creosote and pentachlo- For best performance, as much fabrication should be com-

rophenol, have been confi ned largely to uses that do not pleted prior to pressure treatment to allow all exposed

involve frequent human contact. The exception is copper surfaces to be protected. On-site fabrication of timber bridge

naphthenate, a preservative that has become available more components typically results in breaks in the protective bar-

recently but has been used less widely. rier. Pile tops, which are typically cut to length after installa-

tion, need reapplication of the preservative to the cut ends.

Oilborne preservatives may be visually oily, oily to the Likewise, the exposed end-grain in joints and the immediate

touch, and sometimes have a noticeable odor. However, the area around all fasteners, including drill holes, require supple-

oil or solvent that is used as a carrier makes the wood less mental on-site treatment.

susceptible to cracks and checking and provides a barrier

against moisture, making them the preferred preservative for Periodic inspections should seek to identify cracks, splits,

bridge structural elements. and checks that result from normal seasoning as well as areas

of high moisture or exposed end grain in joint areas. These

Waterborne preservatives are formulations of inorganic areas require periodic reapplication of supplemental preserva-

arsenical compounds that react with or precipitate in treated tive. Supplemental in-place treatments are available in several

wood. The reaction takes place when members are treated, forms: surface-applied chemicals, pastes, diffusible chemicals,

“fi xing” the precipitants (e.g., copper, chromium, and/or ar- and fumigants.

senic) within the cells of the wood to help prevent leaching

and migration. Specifi cations and Guidelines

Waterborne preservatives, however, are used due to their State of Iowa specifi cations pertaining to the handling and

preferred handling properties, clean surfaces, and low preservative treatment of timber used for bridges can be

leaching levels. Waterborne preservative treatments have found in the Iowa Department of Transportation Standard

been found to reduce the mechanical properties of wood Specifi cations, which can be found online at http://www.erl.

under some conditions. Energy-related properties are often dot.state.ia.us/. The American Wood-Preservers’ Association

reduced slightly; however, strength and elasticity properties (AWPA) is the primary standard-setting body for preservative

are generally not affected when correct treatment levels are treatment in the United States. Their timber standards can be

used. purchased online at http://www.awpa.com/standards/ucs.asp.

Properties and uses of in-place preservatives for timber bridges

In-place Active Solvent Internal vs. Leeching or Bridge location Handling and

preservative type ingredient type external diffusing other

Surface treatment Copper naphthe- External Bolt holes, exposed

liquid nate Oil sprayed or Insoluble in water end grain, checks Non-RUP

brushed and splits

Surface treatment External Leech away by pre- Bolt holes, exposed

liquid or powder Borate solutions Water sprayed or cipitation end grain, checks Non-RUP

brushed and splits

CuNap, sodium External Boron & fl uoride Ground line area of

Surface treatment fl uoride, borates Water and covered move into wood, terrestrial piles & Non-RUP

paste Cu-Hydrooxide with wrap Copper stays at under pile caps

surface

Diffusible Boron, fl uoride, Internal Needs moisture to Pile & deep Non-RUP, low

chemical liquid copper Water through diffuse into wood timbers with drill toxicity & ease

drilled holes accessibility of handling

Internal Volatizes into gas & Pile & deep

Fumigant liquid Chloropicrin NA through moves into wood timbers with drill RUP

drilled holes accessibility

Internal Volatizes into gas & Pile & deep

Fumigant solid Solid-melt MITC NA through moves into wood timbers with drill RUP

drilled holes accessibility

Methan Sodium Internal Volatizes into gas & Pile & deep

Fumigant liquid (Vapam) NA through moves into wood timbers with drill RUP

drilled holes accessibility

Granular Internal Volatizes into gas & Pile & deep

Fumigant solid dazomet NA through moves into wood timbers with drill RUP

drilled holes accessibility

Findings and Recommendations bridges constructed with state or federal funding in

The results of this study led to the following conclusions the state of Iowa. If the bridges are being constructed

and recommendations: without state or federal funding, the Iowa DOT specifi -

cations and plant certifi cations are still recommended.

1. Copper naphthenate is recommended as the plant-ap- 4. Treated Southern Pine piles are recommended to have

plied preservative treatment for timber bridge elements. penetration of 3.0 in., or 90% of sapwood penetration.

Copper naphthenate has been tested extensively by The penetration is in accordance with AWPA standards

the FPL in past years and has been shown to have and is currently stricter than Iowa DOT specifi cations.

comparable, if not better, performance to other com- 5. Timber bridge maintenance programs need to be devel-

monly used preservatives, such as creosote. Additional oped and implemented. A maintenance program that

reasons for recommending copper naphthenate include utilizes combinations of inspection tools and various

good handling characteristics, clean surfaces, compara- in-place treatments can easily extend a bridge’s service

ble availability to other preservatives, and the potential life. Future work could entail development of a timber

for lower environmental impact. bridge maintenance program for bridge owners. An

2. During the construction of timber bridges, the Best effective maintenance program contains many compo-

Management Practices should be followed to minimize nents that need to be developed, including 1) person-

environmental impacts to the surrounding ecosystem nel training and education, 2) inspection procedures,

and ensure quality treatment of both plant-applied and 3) evaluation of structure and restoration, 4) in-place

in-place preservatives. In addition to the best manage- treatment procedures, and 5)records and data manage-

ment practices, bridge owners need to insure that pile ment.

tops and cap beams are protected from moisture by use 6. Future workshops and/or short courses presenting

of metal covers and that all fi eld cuts are treated with biodeterioration and preservative concepts to timber

in-place treatments. bridge owners, designers, and inspectors are recom-

3. The AWPA standards are the basis for the Iowa DOT mended in order to implement the information and

specifi cations, which are the regulating standards for procedures presented in this study.

no reviews yet

Please Login to review.